WerkMaster: Always addressing contractor pain points!

Unlock unparalleled efficiency in concrete grinding with WerkMaster's top-tier concrete grinders. Transform surface preparation and floor refinishing across residential, retail, commercial, and industrial projects. Our advanced concrete grinders cater to concrete, terrazzo, stone, hardwood, and VCT surfaces, eliminating the need for labor-intensive hand grinding.

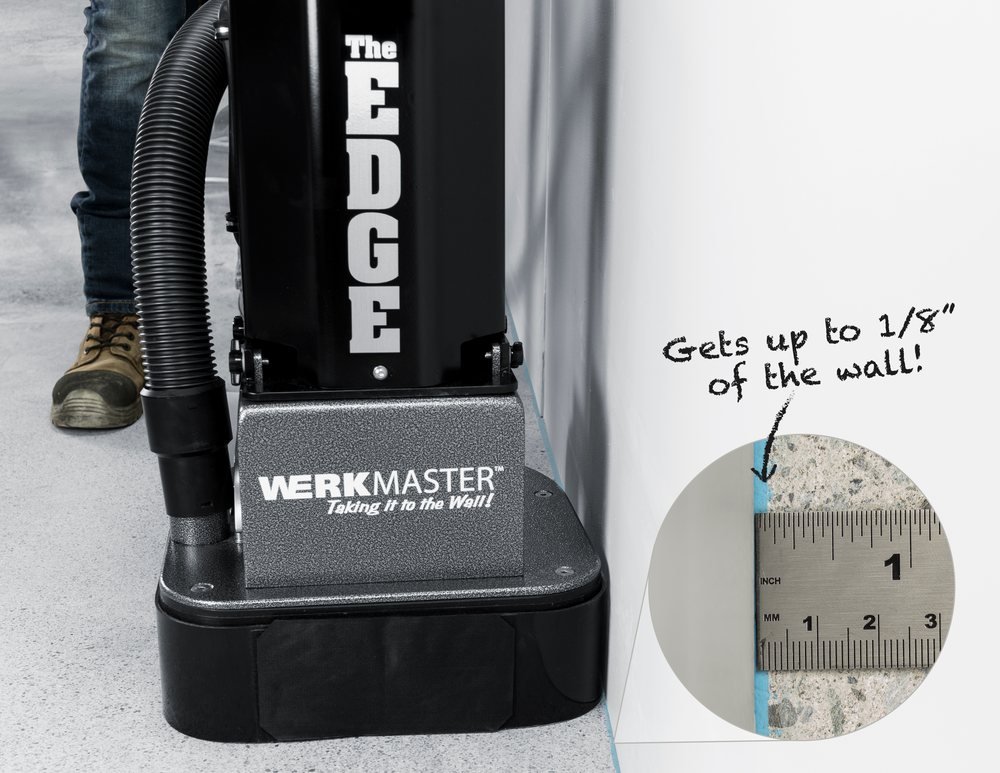

Enjoy seamless edging within 1/8” (3mm) of walls, saving up to 40% in labor costs with our patented Octi-Disc™ Technology. Count on WerkMaster's commitment to professional care, superior craftsmanship, and tailored solutions. Request a quote today from WerkMaster, your go-to source for award-winning concrete grinding equipment.